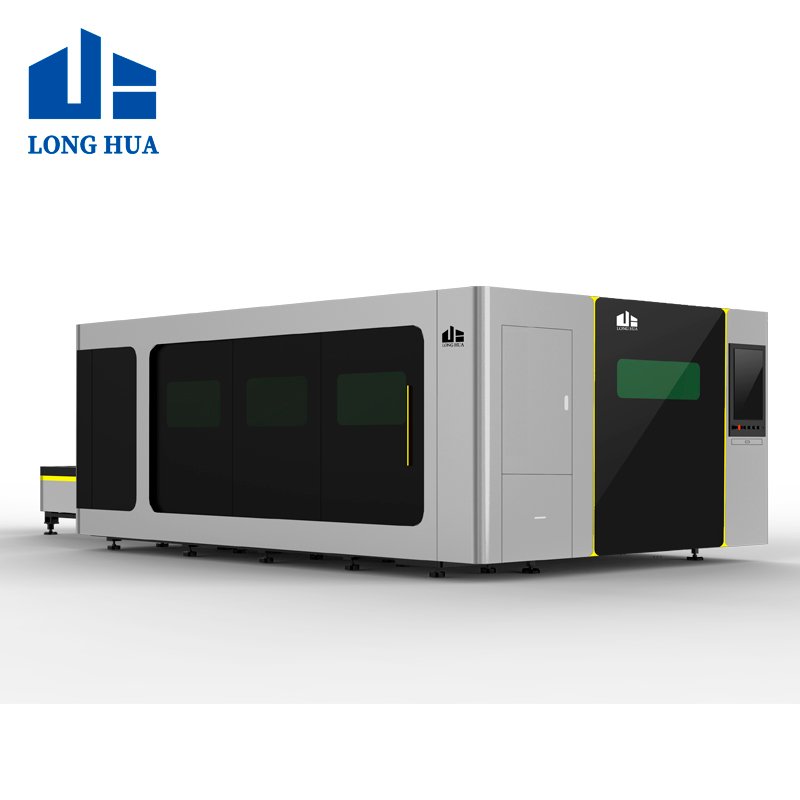

Categories: LP-T, Sheet And Tube Metal Laser Cutting Machine

LP-T Enclosed Sheet and Tube Laser Cutting Machine

LP-T series laser cutting machine adopts fully enclosed shield and exchange platform to ensure a safe and environmentally friendly working environment, and the machines range from 1kw to 60kw, which can achieve stable cutting of 1-100mm metal plates and tubes;

LP-T series is a high-end series of products, fully enclosed cutting of plates and tubes, with zero-second perforation, stable cutting of thick plates, low-pressure cutting, clean cutting and other unique technology to create maximum value for customers

Product advantages

1.Dual worktable, exchange platform, save feeding time

2.full coverage, high configuration, can cut plates and tubes at the same time.

3.automatic focusing, more accurate, more stable support;

4.Multi-angle cutting, beautiful cut, reduce processing costs.

Details display

1.laser head

1.laser head

1.auto-focus laser head

2.Wide adjustment range

3.High cutting precision

4.long service life

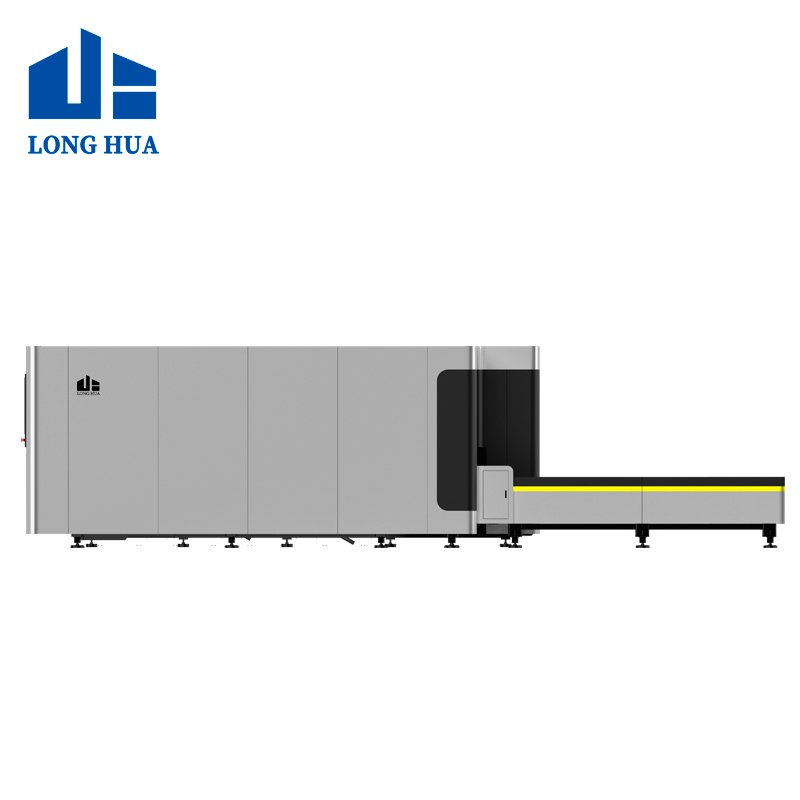

2.High strength steel splicing bed

Each frame of the cutting bed is welded by mortise and tenon connection, with excellent mechanical properties, better stability and firmness.

Visual control system

Various cutting processes

Processing capacity

3.Visual control system

Special software system for cutting machine, with monitoring system and display screen, can monitor the cutting status in real time.

A variety of cutting techniques, beautiful cuts.

4.cross beam

New aluminium alloy beam, high speed and stability, lighter weight, higher density, better rigidity;

Equipped with exchange platform, high-strength tensile structure, high stability and superior dynamic performance.

Data parameters

| Model | LP-T-3015 Fiber Laser Cutting Machine |

| Effective working area | (X=1500mm)*(Y=3000mm) |

| Z axis | 150mm height with the height adjust device |

| Bed structure | High rigidity welded steel framework |

| Table surface | Blade table with water cooling |

| Laser Source | Raycus -1000w/1500W /3000W |

| Laser cutting head | Raytools BMT110/BK06K |

| Guide Rail | 25# Taiwan Hiwin square linear guide rail |

| Transmission | X,Y with helical gear rack ,Z with TBI ball screw |

| Motors and drivers | FUJI servo motor & driver, X,Y axis 850w, Z axis 400w |

| Control system | FSCUT2000E control system |

| Chiller | S&A/Hanli Dual Temperature Control |

| Reducer | Japan imported SHIMPO reducer |

| Lubrication system | One Touch Automatic lubrication system |

| Electronic Proportional Valve | SMC from Japan |

| Electronic Components | SCHNERDER, France |

| Exhaust Fan | Huada, 380V/50HZ/2900RPM |

| Max. idling speed | 80m/min |

| Max. working speed | m/min |

| Software | CYPCUT |

| Working voltage | AC380V, 3 phase,50-60hz or 220V, single phase, 50-60hz |

Sample display

Get a Free QuoteGet a Free Quote

Our representative will contact you soon.