Categories: LE, Sheet Metal Laser Cutting Machine

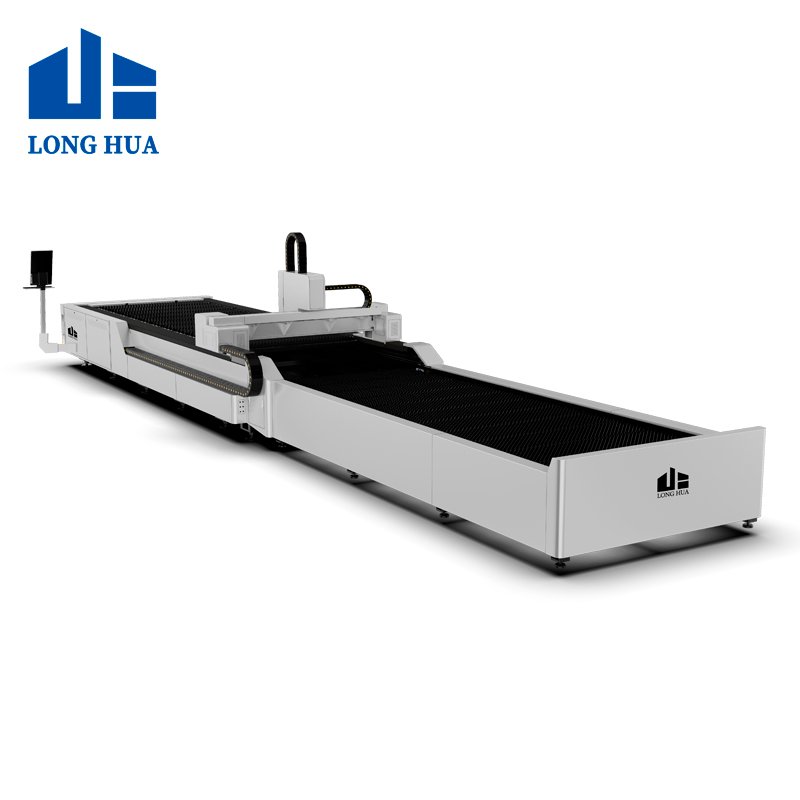

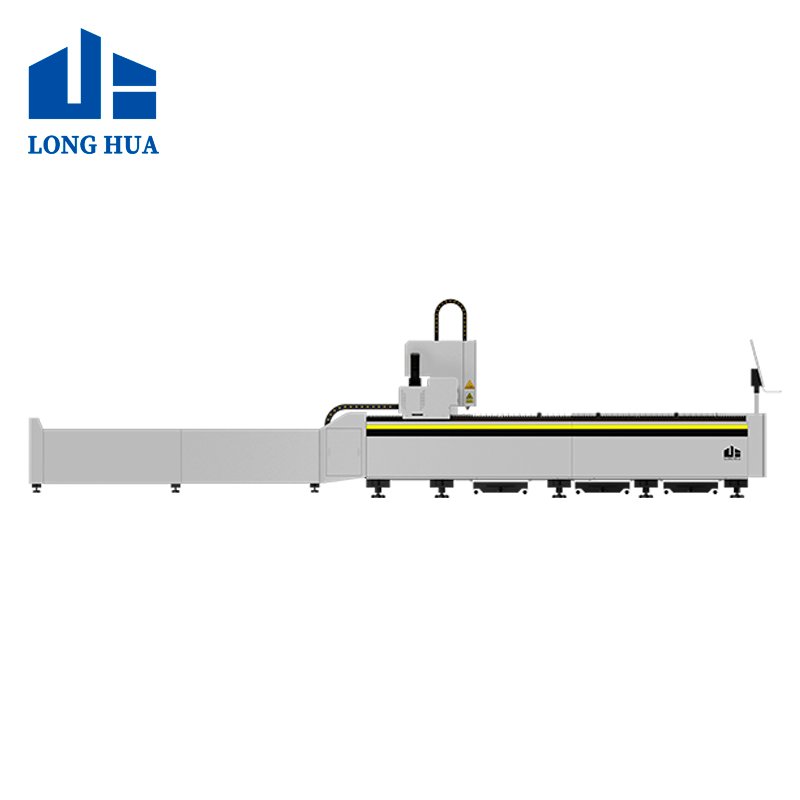

LE Exchange Table Laser Cutting Machine

The LF series is an open structure fiber laser cutting machine, which adopts an exchange platform, a welded casting bed, and a gear rack transmission structure, which effectively guarantees the running speed and accuracy; the mechanical part of the laser cutter head does not contact the workpiece and will not scratch the workpiece surface during operation; while saving materials, it also saves labor costs, and can be widely used in sheet metal cutting to meet customers’ deep processing needs.

Product advantages

1.Ultra-high cutting accuracy (±0.05mm)

2.Leading cutting speed (3-10 times faster than traditional processes)

3.Multi-material compatibility (metal/non-metal)

4.Intelligent and automated integration

Details display

1.Aluminum column beam advantages

1.Aluminum column beam advantages

The beam adopts a lightweight casting structure, which is rough-machined after quenching to eliminate internal stress, and is completed after secondary vibration aging treatment, which better solves the stress generated by casting and processing, thereby improving the stability of the beam.

2.Machine bed technology:

1.Casting bed, one-time processing, to ensure the overall processing quality of the machine tool and the assembly accuracy of the whole machine.

2.The partitioned dust ventilation system handles the dust generated during laser processing, making your production more ecological.

3.Cooling system

3.Cooling system

Standard industrial cold water system, using the world-renowned brand: hanli;

Temperature control accuracy can reach ± 0.5 ℃, cooling is stable;

Two temperature control modes are available, suitable for different occasions;

Multiple settings and fault display functions; Multiple alarm protection functions;

4.Advantages of fiber laser source:

Adopting world advanced technology, famous brand laser, MAX/RAYCUS, to ensure long-term stability;

- Excellent back reflection color protection, safe processing of high reflection materials

- 43% photoelectric conversion efficiency, reduce power consumption.

Data parameters

| Machine model | LE-3015 |

| Laser Source | 1000W /2000W / 300000W |

| Controller | Cypcut, Raytools |

| Working Area(Board processing) | 1500*3000 mm |

| X-axis length | 1515mm |

| Y-axis length | 3030mm |

| Z-axis length | 100mm |

| X-axis motor power | 750W |

| Y-axis motor power | 750W |

| Z-axis motor power | 400W |

| Positioning accuracy of X / Y axis | ±0.05mm |

| Repeated positioning precision of X / Y axis | ±0.02mm |

| Water cooler Power | 1.5KW |

| Guide | Taiwan HIWIN |

| Rack | Taiwan HIWIN |

| Servo Motor | FUJI, servo motor |

| Reducer | Planetary speed reducer |

| Minimum cutting width | 0.08-0.1MM |

| Maximum cutting thickness | Depends on power of laser sources |

| Maximum moving speed | 80m/min |

| Electricity requirements | 380V/50/60HZ |

| Graphic Format Supported | PRO/E.UG, Solid works |

| Acceleration | 1.0G |

| Presser of N2/O2/AIR | 15-20/6-8/15-30 bar |

| Total Weight | 2.5T |

| Work per day | 16H |

| Oil Box | Auto Oil Injection System |

Sample display

Related Products

Get a Free QuoteGet a Free Quote

Our representative will contact you soon.