Categories: Laser Welding Machine, LW

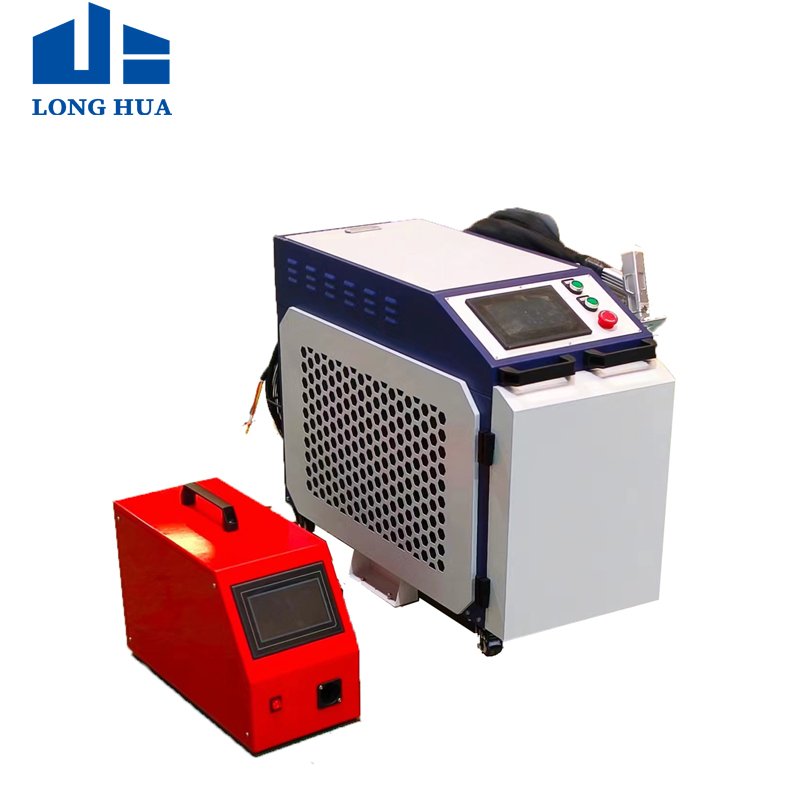

LW 4-in-1 Laser Welding Machine

Metal welding equipment, It is a non-contact welding, which performs cutting, welding, cleaning and other functions on one machine; the operation process does not require pressure, and the operation is simple. It is very suitable for high-efficiency and high-precision operations, especially suitable for automobile, 3C aerospace, electronic components and other industries.

Product advantages

✔ Multi-metal capability

✔ Ultra-fast & clean

✔ Industrial-grade precision

Details display

1.High cost performance,

2. Multifunctional design,

3. Continuous welding

4. Save labor costs

Multiple functions:

laser welding , laser cutting , laser cleaning , cleaning weld bead

Control System

Control system; Flexible operation

SUP latest version control screen,

Support process storage

Support multiple language settings,

Touch screen operation, simple and convenient

Wire feeder; Easy installation

Standard automatic wire feeding system, dual motors, wire feeding forward and reverse rotation and wire feeding speed can be adjusted through the control panel.

Touch screen display, wire feeding speed 15-600cm/min continuously adjustable

Support continuous wire feeding mode, pulse mode, single wire mode, double wire mode, support double wire synchronous adjustment

Data parameters

Data parameters

| Model | LW-4 IN 1 laser welding machine |

| Laser Power | 2000W (Option: 1000W,1500W, 2000W,3000W) |

| Laser Source | MAX (Option: Raycus, IPG, BWT, ) |

| Laser Welding Head | Raytools, WSX, ( optional) |

| Control System | Raytools(Optional:Relfar,Gefasst) |

| Support Languages | 18:Chinese, English, Polish, Turkish, Arabic,Spanish, Russian, French,Italian, and so on Customized language accepted |

| Cooling Method | Water Cooling |

| Positioning Accuracy | ±0.03mm |

| pulse width | 0.1-10ms |

| wavelength | 1080nm |

| focal spot diameter | 0.2-2mm |

| Voltage | 220V 1PH 50HZ/60HZ (Option: 110V) |

Sample display

Laser welding machine is widely used for metal materials, including stainless steel plate, aluminium alloy plate, iron plate, carbon steel and other metals.

It can replace traditional processes such as argon arc welding and electric arc welding. It is used to weld plumbing fittings, tees, valves, showers and is suitable for bathroom industry.

It is suitable for precision welding of stainless steel, titanium alloy and other materials for glass belt buckle and outer frame.

Related Products

Get a Free QuoteGet a Free Quote

Our representative will contact you soon.