Client Overview

Our client, located in Brazil, operates a plant specialising in stainless steel tubes and building materials for construction sites, and was looking to increase their capacity and improve the efficiency of their metal processing with machinery and equipment.

The Challenge

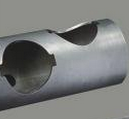

In the process of communication with the sales representative, the customer clearly indicated that there are strict requirements for the thickness and cutting method of stainless steel cutting, and the precision of I-beam cutting is up to 0.1mm; according to the customer’s needs, we recommend 2 different types of machines, namely 3015 Sheet Cutting Machine and T6 Pipe Cutting Machine, to meet the customer’s needs.

The Solution

According to the customer’s needs, we recommended 2 different types of machines, 3015 Plate Cutting Machine and T6 Pipe Cutting Machine, which can cut I-beam steel, and the accuracy and efficiency can be greatly improved; we provided the best price and favourable payment terms for the customer, and finally the customer purchased two machines in total.

Results

After the customer received the equipment, the material waste was reduced by 15%, the efficiency of steel cutting was increased by 180%, and the project delivery time was shortened by 30%, which brought a better experience to the customer and won the customer’s praise.

Conclusion

LONGHUA Laser is committed to solving customers’ problems and providing them with high quality equipment and excellent service. Improve the customer’s return on investment.