1. High quality cast iron, fully resin sand casting molding process

2. Imported high-precision spindle bearings, assembled in Taiwan, with high precision.

3. The feed system adopts linear guide rails to achieve precise movement and positioning,

4. The three-axis ball screw is installed with pre tension, which improves the rigidity of the screw and minimizes errors caused by deformation due to high-speed operation heat.

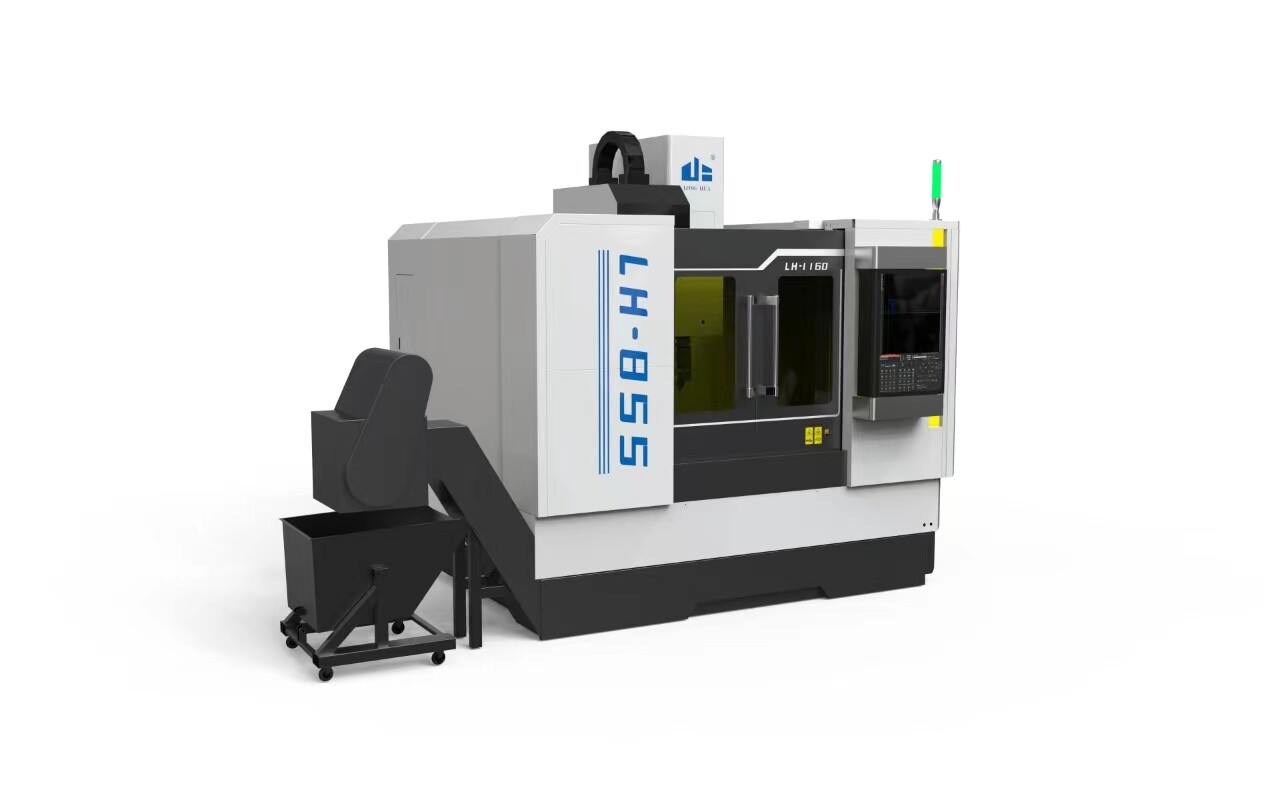

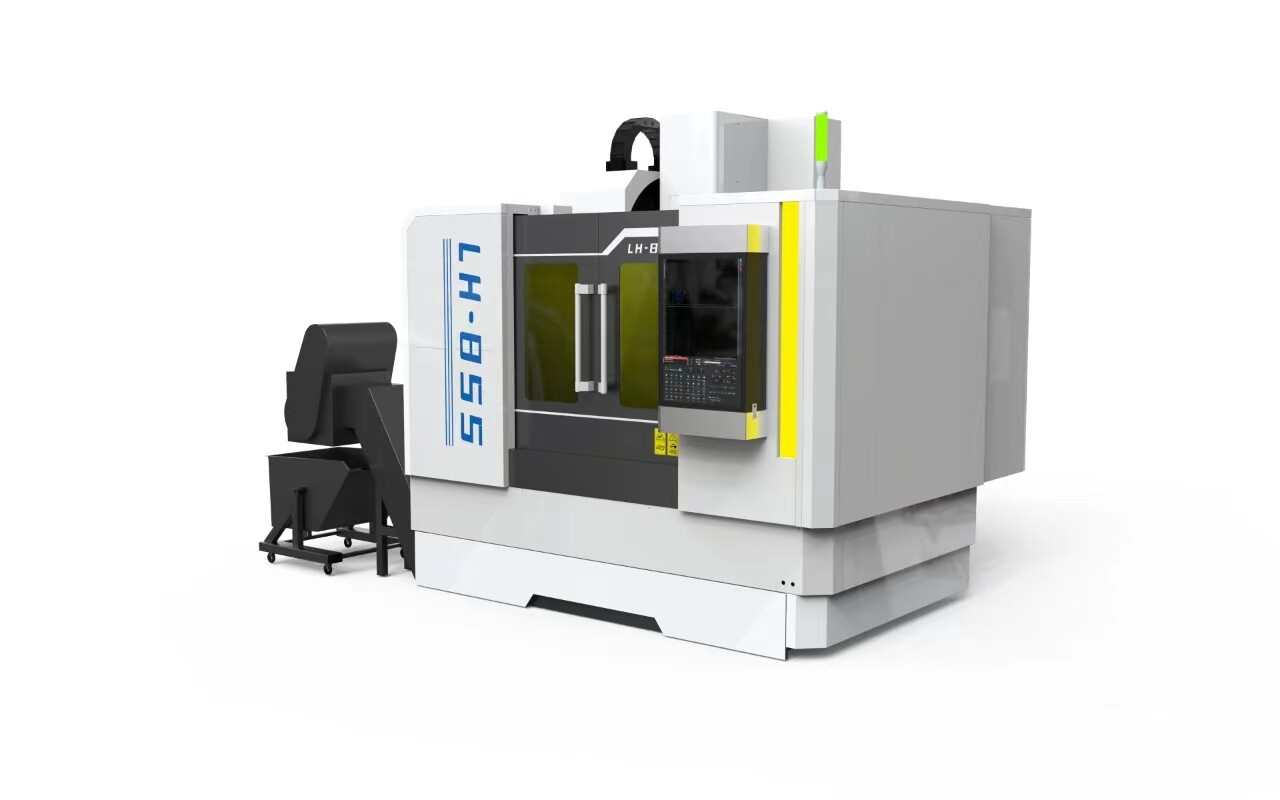

PRODUCT DESCRIPTION

Products Description

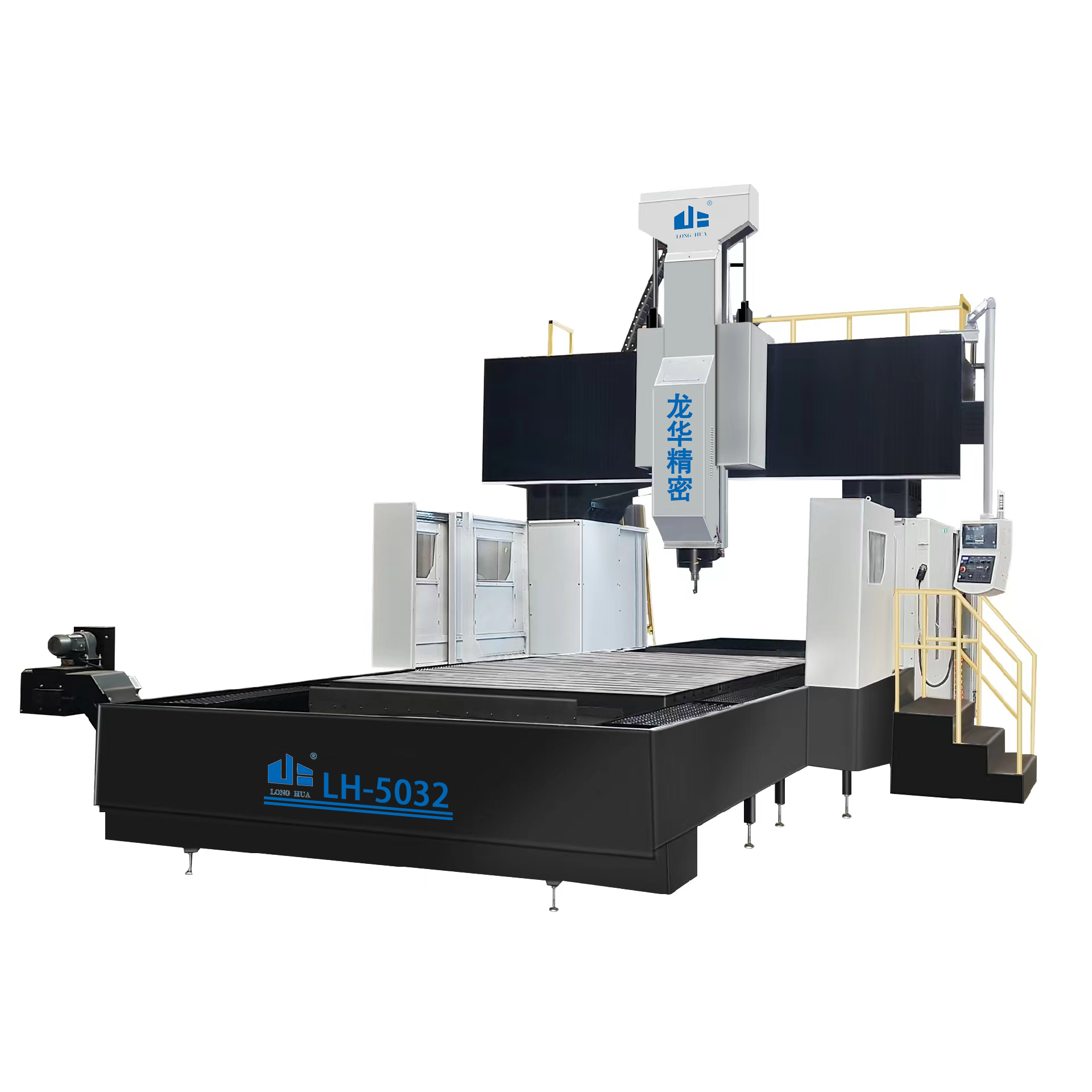

1. High quality cast iron, fully resin sand casting molding process,Improved the seismic resistance and stability of precision of the machine tool, suitable for high-strength and high-precision machining

2. Imported high-precision spindle bearings, assembled in Taiwan, with high precision. The main transmission system adopts an AC servo motor, which is transmitted to the spindle through a synchronous belt, ensuring both rigid tapping and achieving high speed and low noise of the spindle.

3. The feed system adopts linear guide rails to achieve precise movement and positioning, while increasing the resistance of moving parts of the machine tool, enhancing impact resistance, and improving the service life of the machine tool.

4. The three-axis ball screw is installed with pre tension, which improves the rigidity of the screw and minimizes errors caused by deformation due to high-speed operation heat.

Technical Parameters

Professional application

★ Ball screw bearings are imported professional screw bearings, which greatly improve the axial rigidity, accuracy, and impact resistance of the feed shaft.

★The functional components of the machine tool, including the unit spindle, ball screw, linear guide rail, cutting cylinder, lubrication device, tool coupling, screw bearing, etc., are all high-quality products that are reliable and durable

★The assembly process of the machine tool is fine, and the precision of the moving parts is corrected by laser interference and ball bar instrument, achieving stable machining accuracy. The mechanical accuracy is far superior to the national standard..

RELATED PRODUCTS

Message

Leave a message