One machine dual-use, capable of processing metal sheets and cutting metal pipes.

PRODUCT DESCRIPTION

Multi functional Metal sheet and tube integrated fiber laser cutting machine

LF3015-T sheet and tube fiber Laser Cutting Machine

IPG/Raycus/Max/JPT/BWT with Auto Focus Interchangeable Table,

Designed for Cutting Stainless Steel, Titanium, Black and Alloy Steel, Copper and Other Non-Ferrous Metals.

As a cutting tool, the machine uses laser radiation produced by a Raycus Max JPT BWT or IPG source and has a lifespan of up to 100,000 hours. The air flow from the laser radiation source to the cutting zone is carried out through the fiber optic cable.

The machine is equipped with an automatic change station that reduces the time it takes to load and unload sheets to the cutting area without stopping the machine. Replacement time 15 seconds

bed

The internal structure of the bed is made of high-quality metal and consists of many welded special-shaped rectangular tube sections. To increase the strength and possible deformation of the frame, each section is reinforced with stiffeners. After welding, the frame goes through a high temperature annealing procedure to relieve stress in the metal.

Web portals

The whole gantry adopts T6 heat treatment process, which makes the gantry have the maximum strength. Solution treatment increases the strength and ductility of the gantry, optimizing and reducing its weight, resulting in reduced weight and faster cutting.

Advantages of Raytools laser heads:

Advantages of laser head autofocus

Optimized optical configuration with efficient airflow distribution

Auto focus, positioning accuracy 0.05mm

Convenient lens mount for quick and easy access to protective glass

Auxiliary nozzle and shroud design for easy cutting of highly reflective materials and protection from metal splatter

Built-in dual cooling loop channels keep the collimation and focus assemblies at a constant temperature, preventing lens overheating and extending lens life.

Collimating and Focusing Lenses Use single, double or aspherical lenses depending on laser parameters to ensure optimum focusing and beam quality

Control System

CypCut - an independent R&D operating system that perfectly combines high efficiency and ease of use.

The operating system can realize automatic cutting and typesetting (typesetting), support multi-image import, automatically optimize orders, quickly find edges, and automatically position. The control system adopts the best logic programming and software interaction to provide an amazing operation experience, effectively improve the utilization rate of sheet metal and reduce waste. Simple and fast control system, efficient and accurate cutting instructions, improve user experience.

Cutting Samples

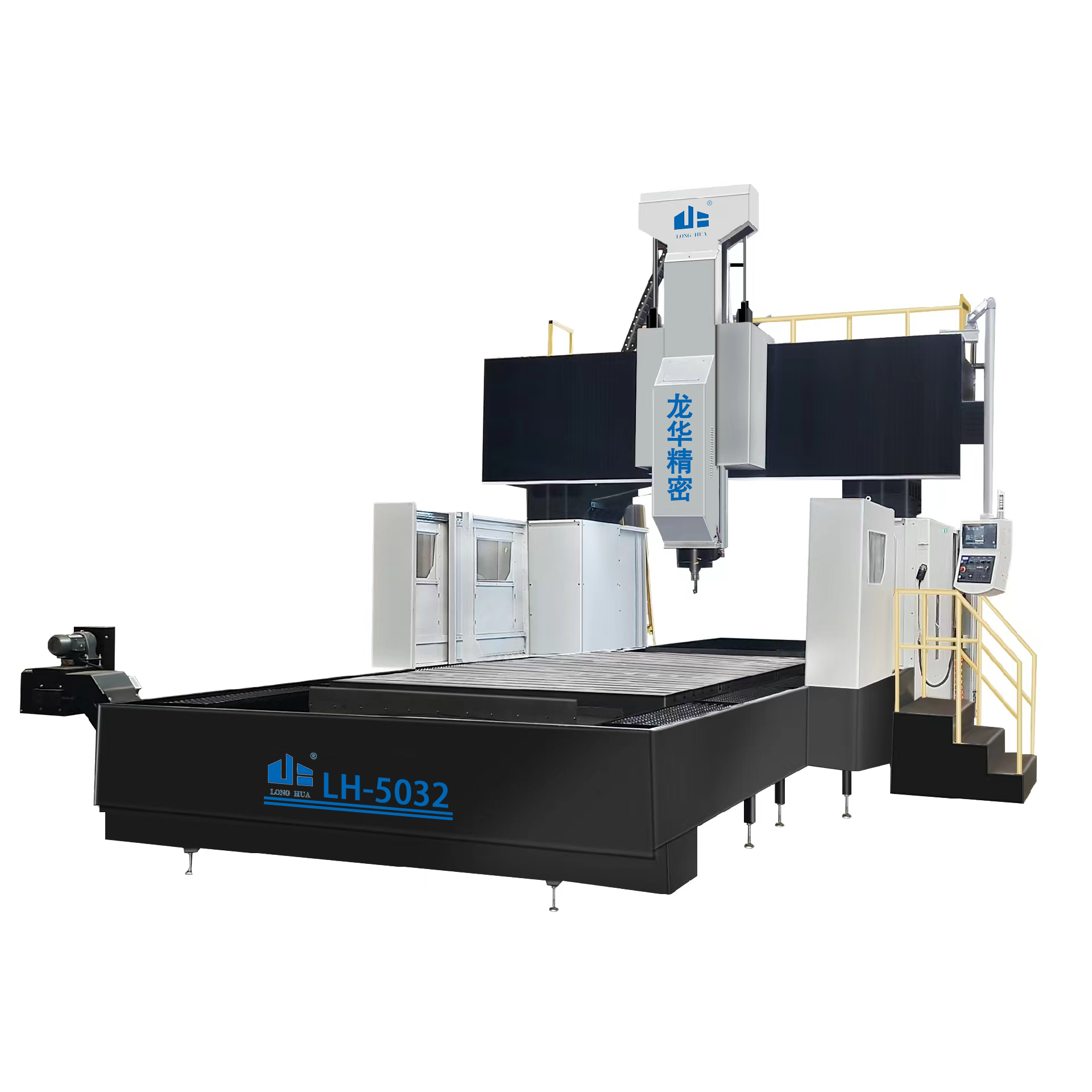

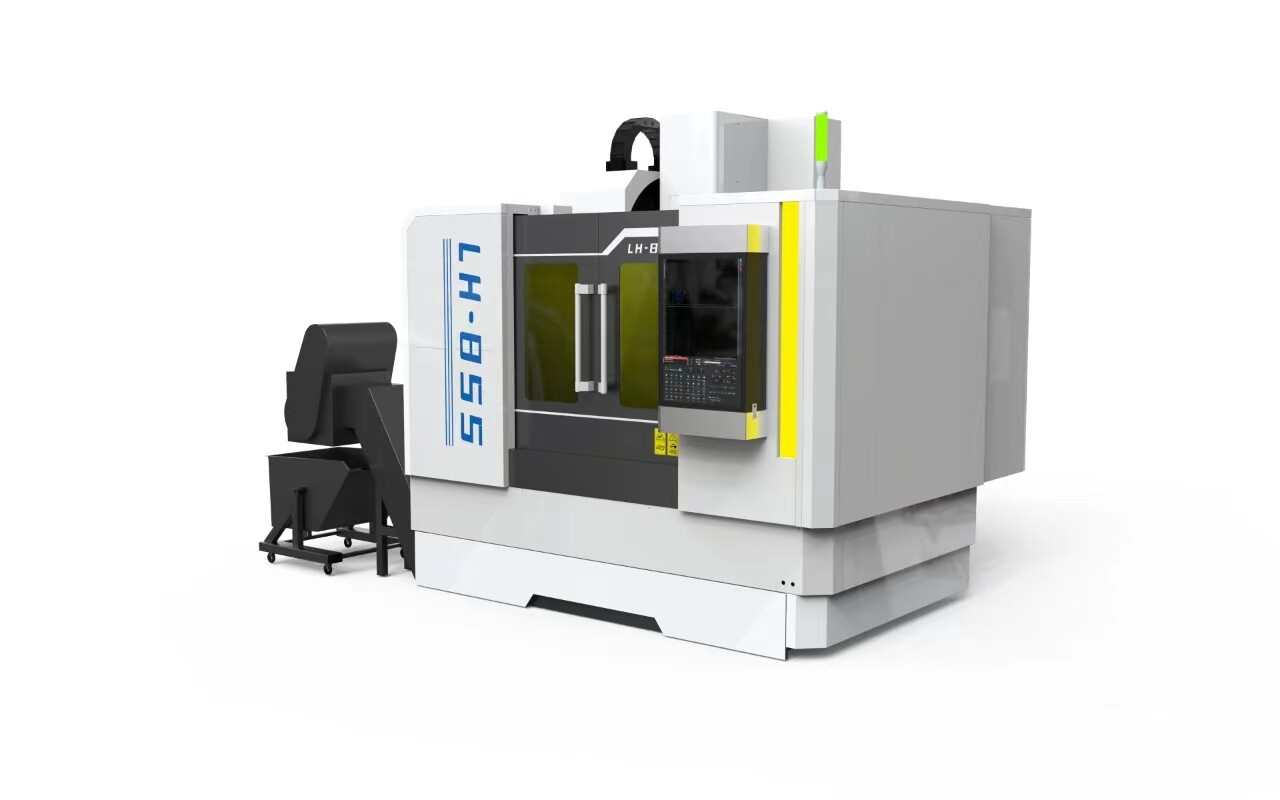

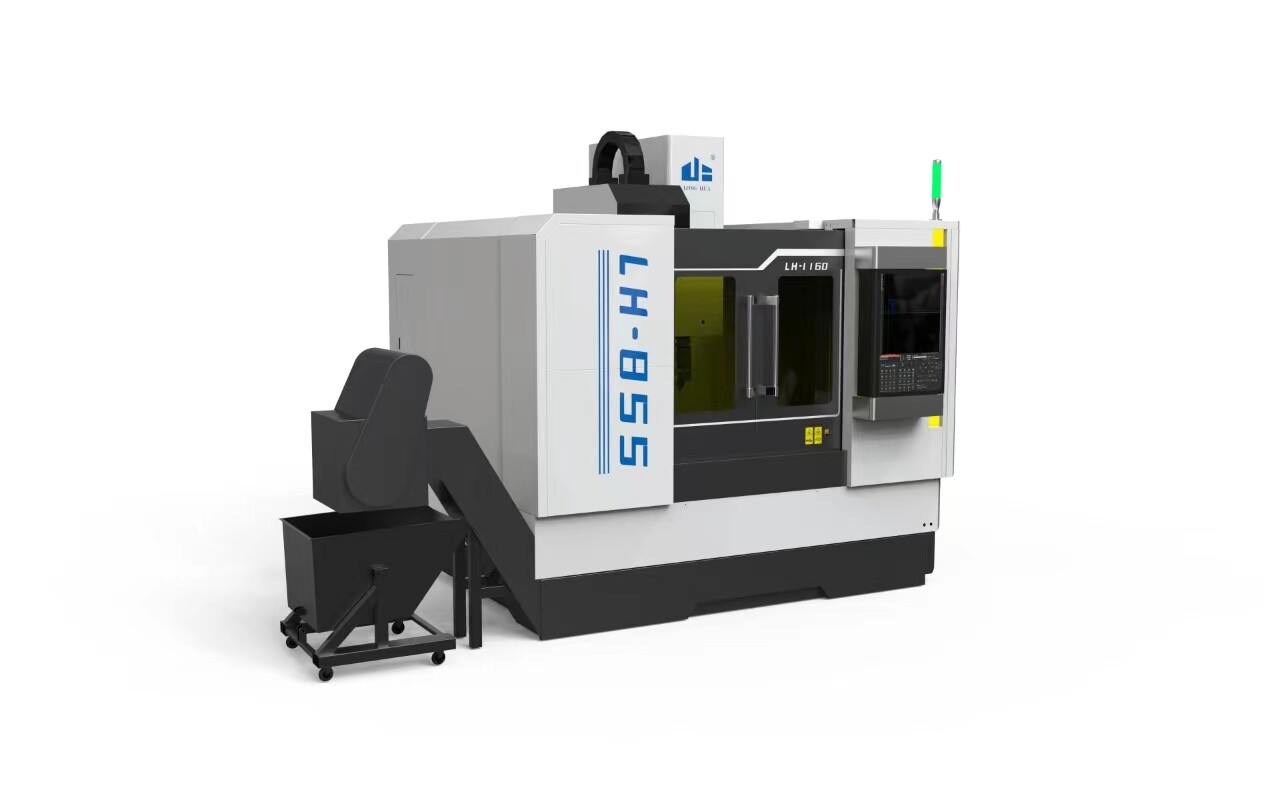

RELATED PRODUCTS

Message

Leave a message