Ideal for cutting metals including stainless steel, aluminum, and copper.

Favored in industries like automotive, aerospace, and electronics due to its high precision and efficiency.

PRODUCT DESCRIPTION

Customizable parameters for metal sheet laser cutting machine

LP SERIES Sheet Metal Laser Cutting Machine

This laser cutting machine adopts a fully enclosed structure and adopts laser radiation protection glass that meets occupational health and safety regulations. When the equipment is running, the light pollution and smoke pollution caused by laser cutting are reduced. The cast iron bed is used to increase the structural strength of the bed; the uniquely designed exchange platform can be exchanged within 15 seconds, which greatly improves the cutting efficiency.

CYPCUT control system

It supports image data formats such as Al, DXF, PLT, Gerber, and LXD, and adopts the G code of the international standard Cypcut control system created by software such as MaterCam, Type3, and Wentai.

Automatic optimization when opening/importing DXF and other external files, including: removing duplicate lines, merging connection lines, removing small graphics, automatically distinguishing between internal and external models, and sorting. Each of the above functions can be defined or executed manually.

Supports common editing and typing functions, including: zoom in, zoom out, pan, mirror, rotate, straighten, copy, combine, etc.

Use the easiest way to install leads, gap compensation, micro headers, jumpers, inner and outer leads, gapless lead seals, and more.

Accommodation requirements

The entire machine must be at least 1 meter away from obstacles. The whole machine must be kept away from the source of the earthquake.

The flatness of the placement area should be less than 5 mm. Voltage fluctuations across the machine must not exceed 5%.

Cutting Samples

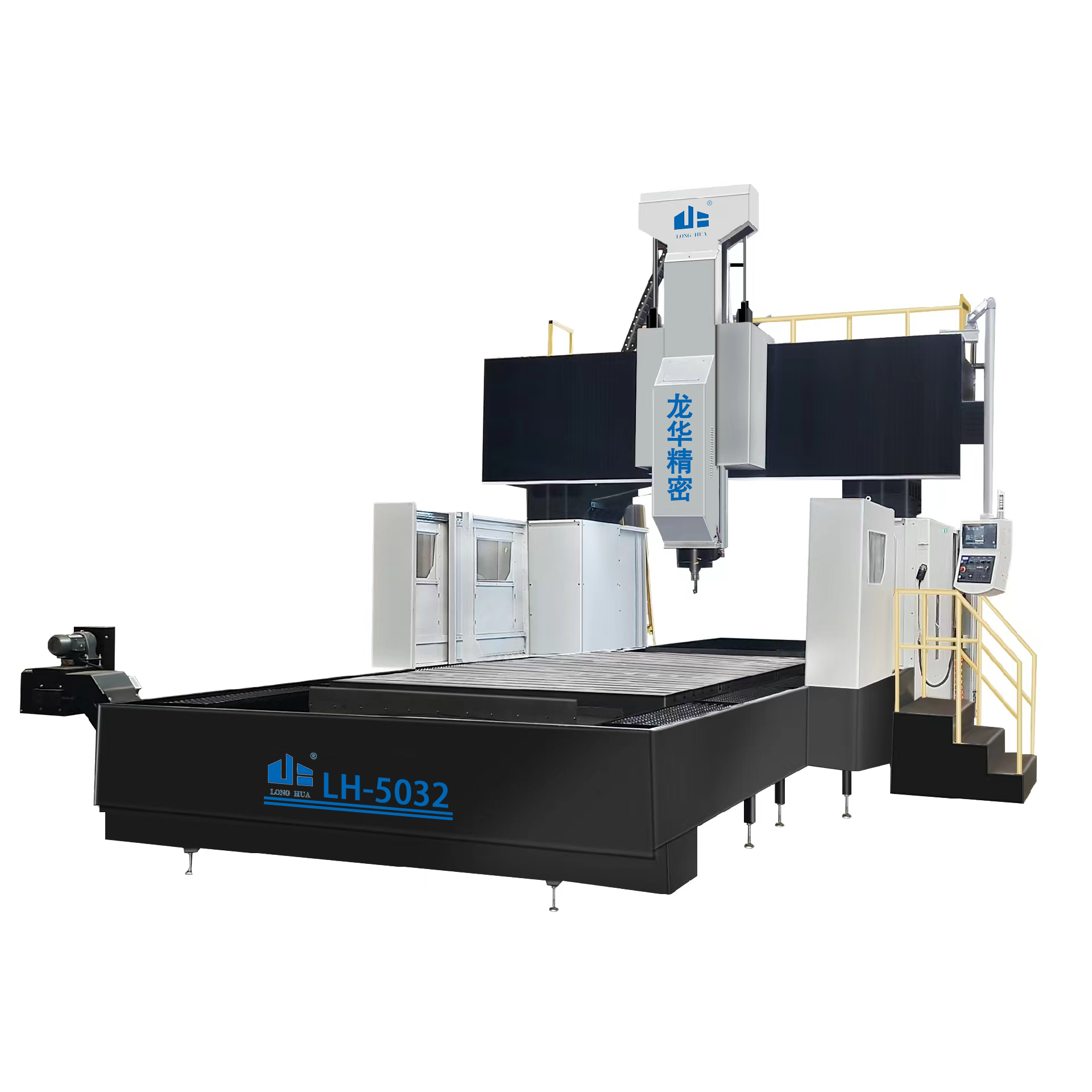

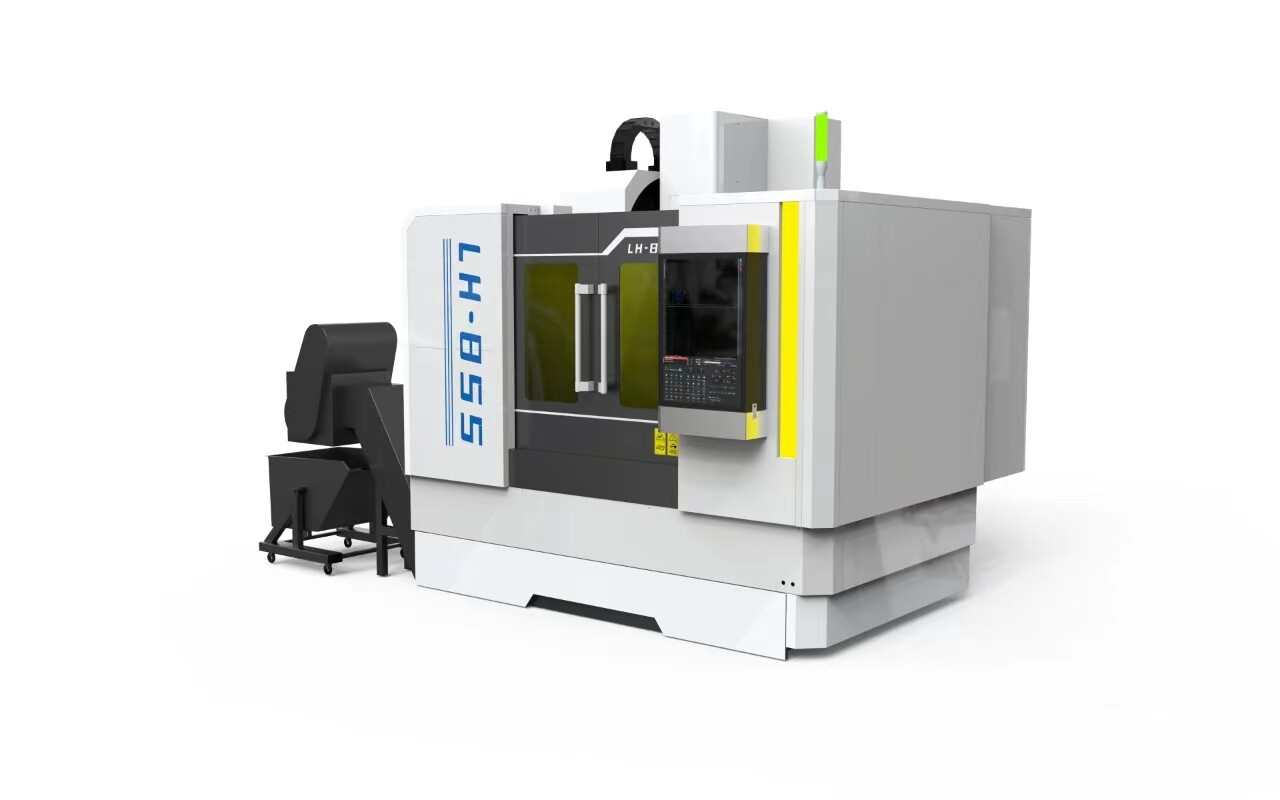

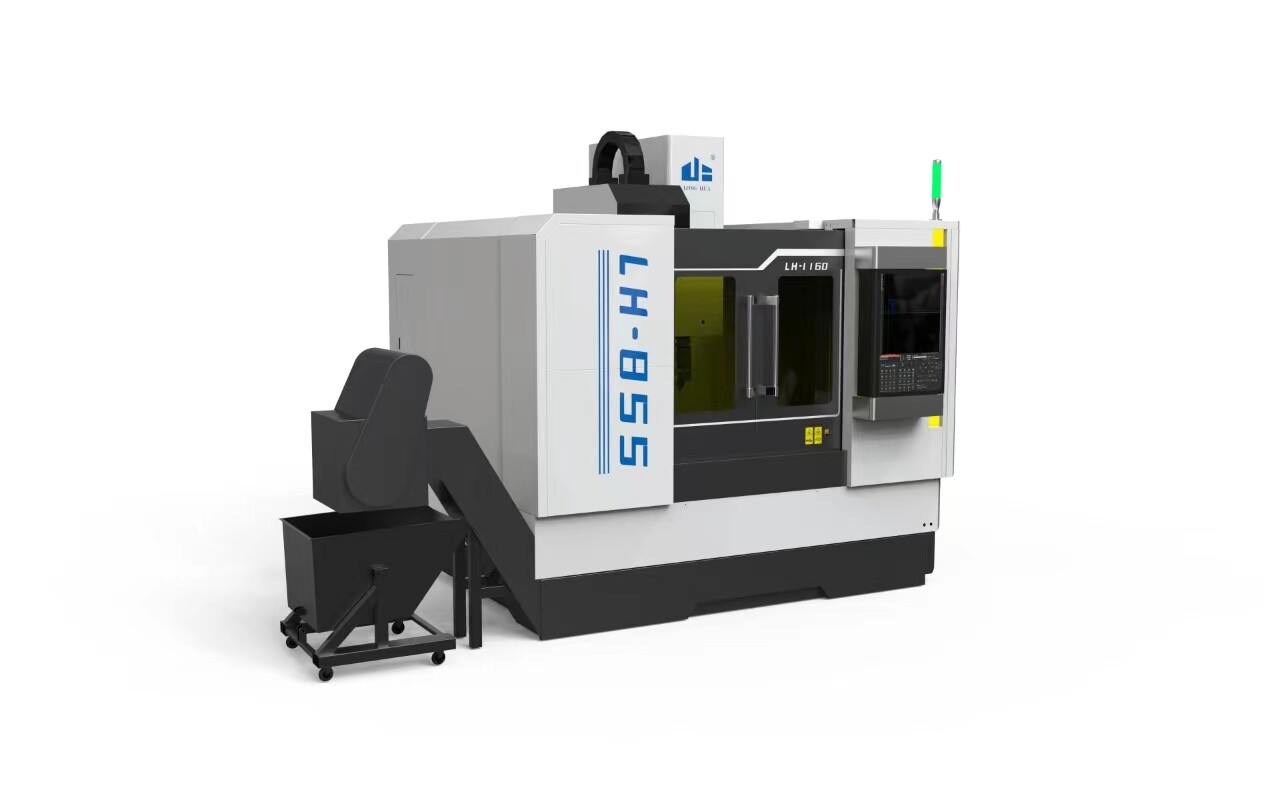

RELATED PRODUCTS

Message

Leave a message