Ideal for cutting metals including stainless steel, aluminum, and copper.

Favored in industries like automotive, aerospace, and electronics due to its high precision and efficiency.

PRODUCT DESCRIPTION

Customized Parameters For Metal laser Cutting Machine

Advantage

Welded frame through high temperature annealing process

Quality correspondence of laser machines

Components from the world's leading manufacturers Yaskawa, HIWIN, Raytools, Raycus, Max, IPG

Popular and easy-to-understand CypCut software in English

Separate electrical cabinet with air conditioning system

wireless remote

Metal laser cutting machines feature fast cutting speeds, low maintenance costs, powerful designs, and low energy consumption.

Low power consumption and high energy efficiency are achieved by using a fiber laser as the radiation source. In addition to the high efficiency in its class, there are many advantages to this type of laser.

Welding bed

The structure of the frame consists of inserted thick high-strength steel tubes, cut using laser machining. Automatic welding is adopted to ensure that the welding seam is not easy to break. The bed is annealed, vibrated and naturally aged to eliminate internal stress, so that the bed maintains good mechanical properties and has good tensile properties, strength and hardness.

Portal Aluminum

The whole gantry adopts T6 heat treatment process, which makes the gantry have maximum strength. Solution treatment increases the strength and ductility of the gantry, optimizing and reducing its weight for reduced weight and faster cutting speeds.

Autofocus laser head

The autofocus laser cutting head is driven by a built-in motor. The focusing lens is driven by a linear mechanism and automatically changes position within a specified range. The continuous focus can be set through the program to complete the rapid blanking of thick plates and the cutting of different thicknesses of different materials.

Cypcut Control System

CypCut - an independent R&D operating system that perfectly combines high efficiency and ease of use.

The operating system can realize automatic cutting and nesting (typesetting), support multi-graphic import, automatically optimize orders, quickly find edges, and automatically position. The control system adopts the best logic programming and software interaction to provide an amazing operation experience, effectively improve the utilization rate of sheet metal and reduce waste. Simple and fast control system, efficient and accurate cutting instructions, improve user experience.

Cutting Samples

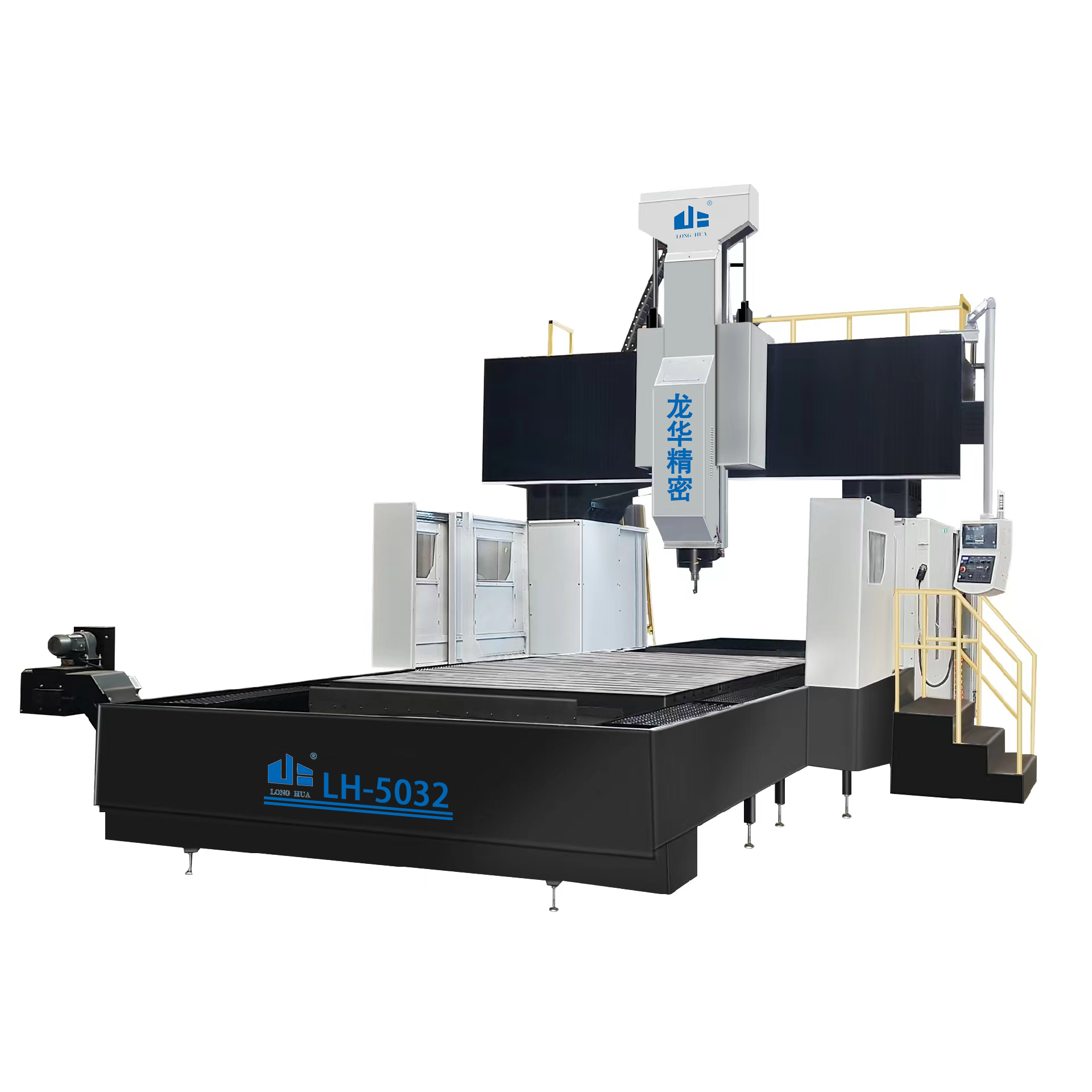

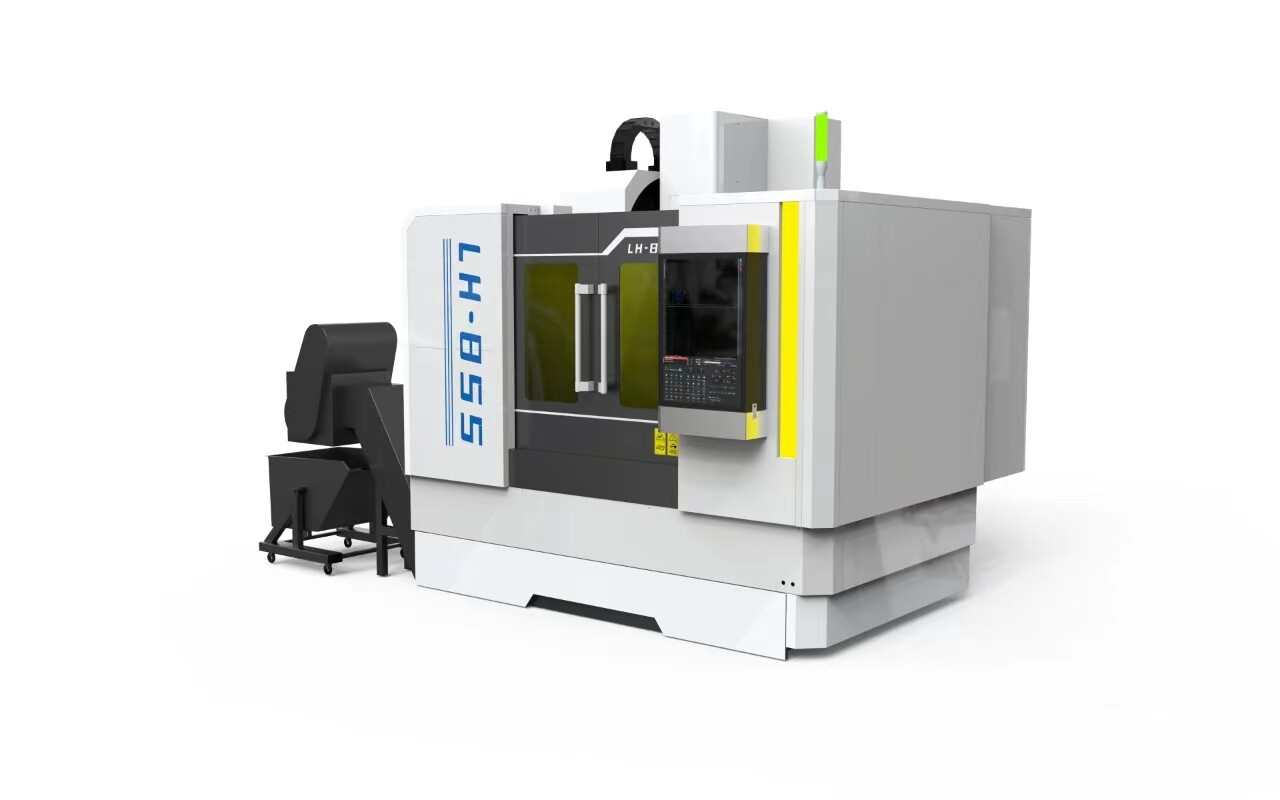

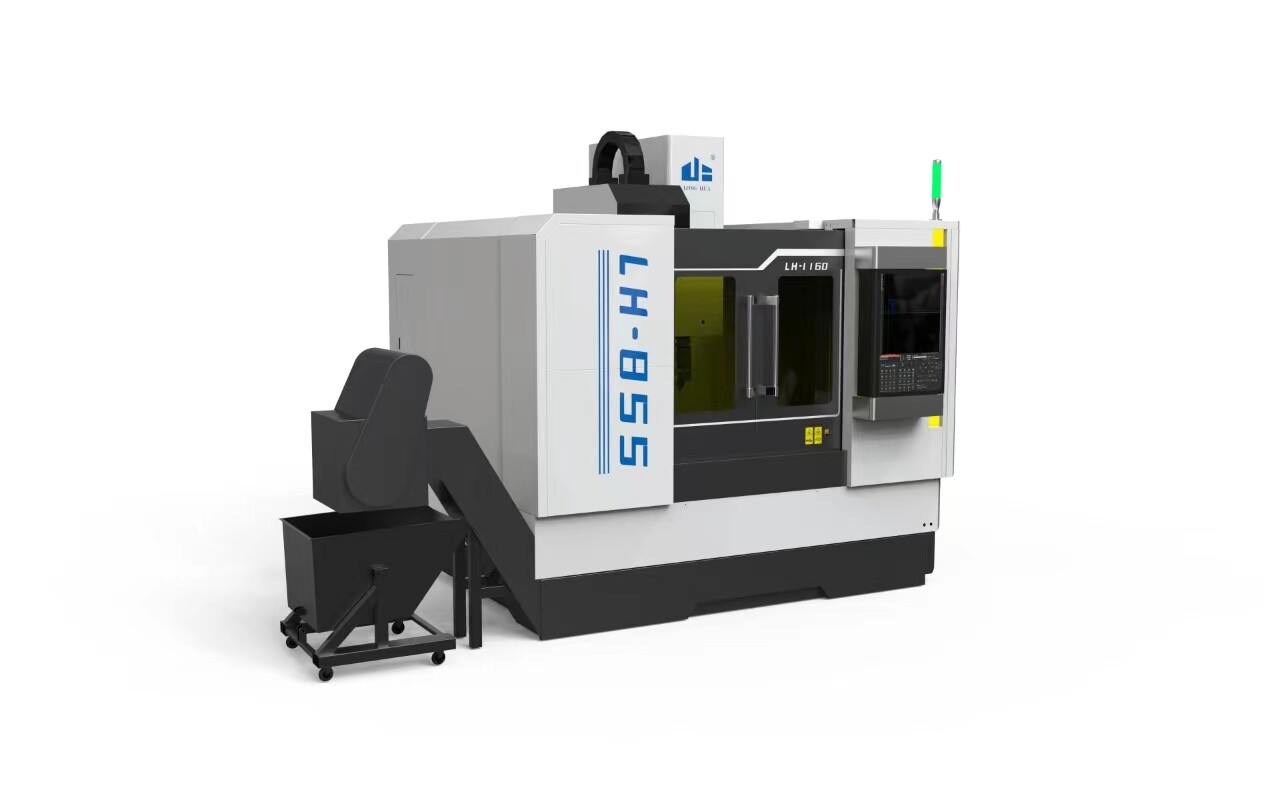

RELATED PRODUCTS

Message

Leave a message